Exactly How Commercial Scales Improve Accuracy in Manufacturing and Logistics

Industrial ranges are integral to the precision required in production and logistics, as they straight influence the accuracy of weight measurements necessary for reliable production and stock methods. Industrial Scales. By ensuring that materials are evaluated properly, companies can mitigate errors that can bring about considerable monetary effects. Furthermore, the development of sophisticated modern technologies in weighing systems is transforming traditional processes. Nonetheless, recognizing the complete level of these innovations and their implications for future operations invites a closer evaluation of exactly how advancing techniques can redefine precision criteria in the industry.

Value of Accuracy in Procedures

In the world of production and logistics, accuracy is the keystone of operational efficiency. Exact dimensions are crucial for maintaining quality assurance, maximizing source allowance, and making sure compliance with market criteria. When procedures count on exact information, businesses can minimize waste, improve production timelines, and enhance general productivity.

The relevance of accuracy expands past straightforward dimension; it additionally affects decision-making processes. Precise weight readings can establish suitable supply degrees, simplify supply chain logistics, and facilitate precise invoicing. In addition, inaccuracies in measurements can cause pricey errors, such as overproduction or taking too lightly material requirements, which can threaten task timelines and profitability.

By carrying out strenuous dimension criteria, companies can identify ineffectiveness and pass enhancements, inevitably leading to boosted consumer contentment. Hence, spending in accuracy dimension devices, such as commercial ranges, is not simply a technical consideration but a tactical vital for success in the manufacturing and logistics industries.

Sorts Of Industrial Scales

Various kinds of commercial ranges play an essential duty in accomplishing the precision necessary for effective manufacturing and logistics procedures. Each type is created to satisfy details needs, making certain exact dimension of elements, products, and products.

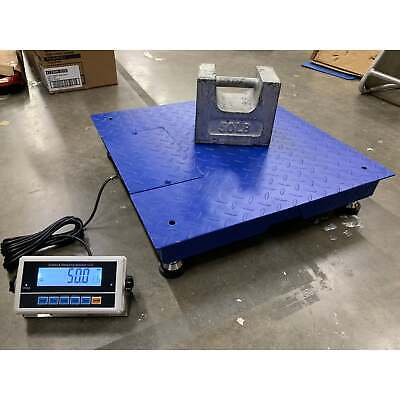

One typical type is the platform scale, which gives a flat surface area for considering large products or bulk products. These scales are usually utilized in stockrooms and shipping facilities. One more kind is the bench scale, commonly smaller and utilized for considering individual packages or smaller sets of products. These scales are vital in top quality control processes. Industrial Scales.

For applications where accuracy is essential, logical balances are used. These high-accuracy ranges are utilized in labs and study settings to measure little amounts with utmost accuracy. Floor scales, designed for heavy-duty considering, are perfect for evaluating huge pallets or containers, often integrated with forklifts for effectiveness.

Additionally, tons cells are made use of in various applications for real-time weight dimension and data collection. Each of these ranges contributes distinctively to the functional performance, guaranteeing that businesses can preserve precision throughout their manufacturing and logistics procedures. Recognizing the kinds of commercial ranges is necessary for optimizing performance and accomplishing functional excellence.

Influence on Stock Management

Precise evaluating is critical for efficient supply management, as it straight influences supply precision and operational efficiency. In manufacturing and logistics, exact dimension of items and materials makes sure that stock documents mirror real supply degrees, reducing discrepancies that can result in overstocking or stockouts. Industrial scales offer the needed precision to weigh things properly, making it possible for organizations to keep a trusted supply system.

In addition, exact considering adds to far better projecting and preparation. With exact information on stock degrees, organizations can make educated decisions concerning procurement and production schedules. This reduces the risk of excess supply, which can bind resources and boost storage costs, in addition to protect against shortages that may interrupt procedures.

In addition, the integration of industrial scales with stock administration systems assists in real-time monitoring of supply movements. This enhances the procedure of upgrading supply records, boosting openness and liability throughout the supply chain. Inevitably, accurate weighing not just sustains effective inventory monitoring yet likewise drives overall functional effectiveness, making it possible for businesses to react quickly to market demands and keep an one-upmanship in their corresponding markets.

Enhancing Quality Assurance

Efficient inventory management not just guarantees optimal supply degrees but also lays the foundation for durable quality assurance processes. Industrial ranges play an essential role in improving high quality control by offering exact weight dimensions that are important for keeping product honesty. Constant weight verification makes it possible for producers to stick to specs, ensuring that each product meets the necessary top quality requirements.

In high-stakes environments, such as food manufacturing their website or pharmaceuticals, also small weight inconsistencies can cause considerable conformity problems. By incorporating industrial ranges right into the assembly line, business can monitor item weights in real time, enabling prompt corrective actions if abnormalities are found. This aggressive approach reduces waste and improves general product dependability.

Additionally, exact considering facilitates better solution of raw products, which is vital in sectors such as cosmetics and chemicals. By making certain that ingredient proportions continue to be regular, makers can accomplish remarkable product quality, enhancing customer satisfaction and reducing returns.

Future Fads in Considering Modern Technology

The future of considering innovation is poised for significant developments driven by automation, connectivity, and data analytics. As sectors advance, the assimilation of sophisticated sensing units and IoT (Web of Things) capabilities will enable real-time surveillance and coverage of weight data. This connectivity will not just important site boost functional effectiveness however likewise help with anticipating upkeep, minimizing downtime and enhancing productivity.

Additionally, the consolidation of expert system and artificial intelligence algorithms into weighing systems will certainly enhance information analysis capacities. These modern technologies can recognize patterns and abnormalities, allowing for even more educated decision-making and optimized supply chain monitoring. Moreover, the increase of cloud-based solutions will certainly allow seamless data sharing across systems, making sure that stakeholders have access to up-to-date info whatsoever times.

Sustainability will also play an essential duty in future weighing innovation. As organizations aim to decrease their carbon footprint, evaluating systems that include energy-efficient designs and materials will certainly become progressively important. In addition, developments in electronic considering scales will certainly sustain far better resource management by offering exact dimensions that lower waste.

Verdict

In conclusion, industrial scales dramatically enhance accuracy in manufacturing and logistics by supplying precise weight measurements necessary for reliable operations. Their function in stock monitoring, quality control, and integration with innovative technologies emphasizes their relevance in optimizing and decreasing disparities resource allowance. As industries proceed to progress, the adoption of innovative considering services will better support operational effectiveness and decrease waste, inevitably adding to improved performance and competitiveness in the market.

One usual type is the system scale, which gives a flat surface area for evaluating large products or bulk materials. Another kind is the bench scale, commonly smaller and used for considering individual bundles or smaller sets of products. Flooring scales, created for durable considering, are optimal for considering big pallets or containers, often incorporated with forklifts for performance.

Industrial scales give the required accuracy to weigh products properly, allowing organizations to preserve a dependable supply system.

Comments on “Advanced Attributes of Modern Industrial Scales for High Performance”